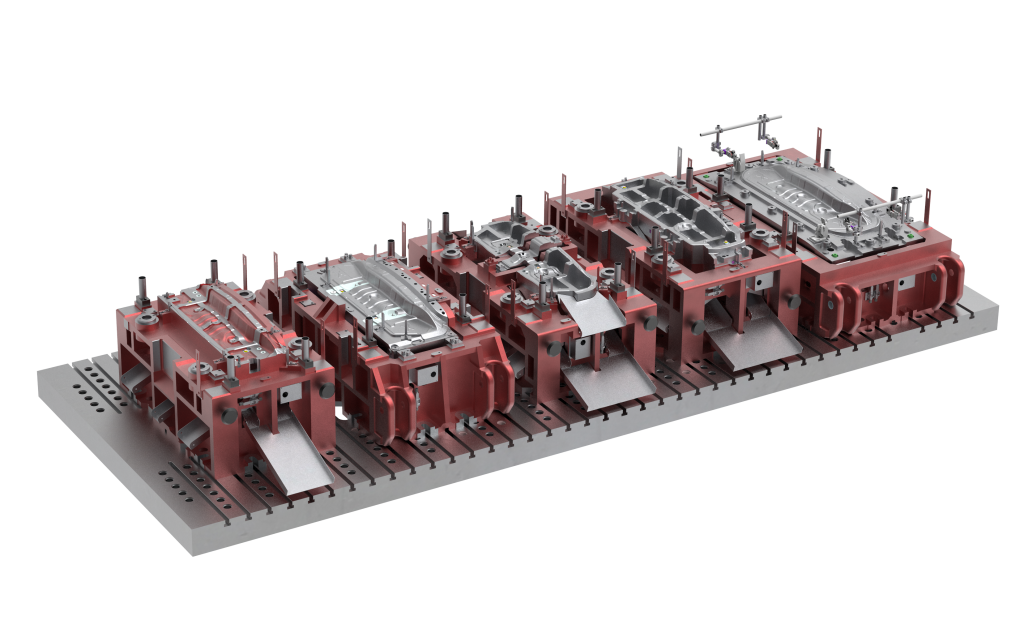

Pass away production can be a complex and costly procedure. The following details developed by our market professionals at The DIAN Stamping will assist offer some insight into the production procedure, the necessary devices, and fundamental die anatomy.

WHAT IS A DIE IN MANUFACTURING?

A die manufacturing is an accuracy tool that cuts and forms metals into practical shapes. The two die halves are positioned inside a press that can produce adequate force to carry out the needed die functions. A die can carry out 4 important functions: finding, securing, working, and launching. Out of these 4, value-added operations just take place throughout the working function of the die. This work consists of however is not restricted to cutting, flexing, piercing, embossing, forming, drawing, extending, creating, and extruding.

WHAT ARE THE COMPONENTS OF A DIE?

Upper and Lower Shoes

Upper and lower shoes are the base where all other die elements are connected, and they are normally made from cast iron or steel. Pass away shoes should withstand deflection throughout the operation of the tool.

Guide Pins and Bushings

Guide pins and bushings are crucial elements that keep the finding capability of a die. Guide pins are generally made from solidified steel and connected to among the die shoes, going into the bushings discovered on the opposite shoe to find the two pass away halves. Bushings tend to be made from a softer product, fertilized bronze, to promote wear on the bushing instead of the pin.

Punches

Punches are the male functions that deal with a die steel to impart the value-added shape to the product. Punches can be utilized as forming or cutting tools, depending upon their required application. Forming and cutting punches are made from tool steel to fight the high wear the information sustain.

Pass Away Steels and Cavities

Pass away steels and cavities are the opposite, shape of punches; these information likewise assist form the product. For forming tools, they basically mirror the punch plus product density. The shape is likewise mirrored for cutting steels however is balanced out bigger to accommodate punch-die damage. This balanced out permits correct cutting clearances and the cut product to fail the tool.

Stripper Pad

This element’s main function is to pull or remove the product off the punches after journalism has actually cycled to the bottom. Normally driven by springs, however in some cases strong, the stripper springs are compressed throughout the downstroke of journalism. Throughout the upstroke, the springs go back to their initial length, pressing the stripper pad and the product off the working punches.

Stop Blocks

Lined up with die webbing and parallels, these information assist avoid disastrous damage to the tool throughout a crash occasion. It is likewise typical to have a slot ground at the top of the block that is utilized for die set-up.

Pilots and Gauges

Pilots and evaluates assistance find the strip or a blank before cutting and forming happen.

Springs

Nitrogen, coil, or neoprene springs are utilized to use holding pressure to the part, strip the part off the tooling, or return information to a home position.

WHAT ARE THE DIFFERENT TYPES OF DIES?

PROGRESSIVE DIE

Progressive passes away consist of several operations, forming and cutting on one die shoe. For instance, an easy progressive die might appear like this:

Station One– Pierce Operation

Station Two– Draw Operation

Station Three– Idle

Station Four– Flange Operation

Station Five– Cut-Off

The space in between each station or the product’s development is a defined range, called the pitch. The part remains connected to the coil through a provider strip till it is cut off at or near the last station.

Progressive passes away tend to be able to run faster than their bigger transfer pass away equivalents. Progressive passes away are likewise easier to establish as all stations are connected to a single die set. In addition, product development is managed by a coil feed system, removing the requirement for intricate transfer systems. Progressive passes away usually produce smaller sized, less complicated parts.

TRANSFER DIE

Transfer passes away consist of one operation per die set. The product is then moved to the next die for a subsequent operation. Each die set carries out a particular operation. A common development would appear like this:

Operation One– Blank Die

Operation Two– Draw Die

Operation Three– Pierce and Trim Die

Operation Four– Flange Die

The product is separated from the coil in the very first die, so other transfer devices need to be utilized to move the part from die to pass away. Due to the big part sizes that move passes away fruit and vegetables, numerous transfer lines need numerous presses to produce a part.

Transfer passes away can dealing with bigger and more complicated parts than progressive passes away. The disadvantage is that pricey and complex transfer devices is required to move the product throughout the development. In addition, considering that each station is its own die, a greater financial investment is needed to make a transfer pass away line when compared to a progressive die.

PASS AWAY BUILDING MATERIALS

Equipment

Computer System Numerical Control (CNC) Milling Machine

CNC Wire Electrical Discharge Machine (wEDM).

Surface area Grinder.

Drill Press.

Conventional/Sinker EDM.

Coordinate Measuring Machine (CMM).

Computer-Aided Design (CAD) Software.

Computer System Aided Manufacturing (CAM) Software.

catia and UG

PASS AWAY MAKING PROCESS.

The die-making procedure begins with style. Initially, the part is created to the consumer’s requirements, and after that the die is created to produce that part. Considering that this style starts the circulation of production, it is crucial that as lots of issues, and possible issues, as possible are captured in this phase. If not, all continuing activities will likely suffer.

Next, producing the tool can start. Product type is chosen based upon the die requirements. These requirements might consist of part product, part shape, determined tonnage, and yearly output. Steel is extremely the most typical product utilized, however the die products can vary from carbide to wood. For many applications, the product needs to be square for precise machining. Squared product can typically be bought from the provider or milled square on a CNC.

When the product is on the CNC, information (pass away elements) can be machined to end up measurements or have additional stock left for a later grind, hard-milling, or wire EDM procedure. Threads and screw holes are typically completed throughout this procedure, while dowels are normally left little to enable a more accurate finishing action.

Next, the required working information will be heat dealt with. When information are anticipated to be covered before they reach the last consumer, the heat-treat supplier need to utilize a procedure suitable with the future finishing. Otherwise, the required product qualities might not be accomplished.

When the product is heat-treated, surface machining can start. Numerous surface machining techniques can be utilized depending upon needed tolerances, surface area finishes, and store capability. These techniques consist of wire EDM, jig grinding, polishing, surface area grinding, and tough milling.

When machining is total, the die can be put together, dry run (cycled with a crane or hydraulics to confirm no harmful disturbances), and put in a press for tryout. Tryout intends to evaluate the tool for part precision, consistency, and production ability.

REQUIRED HELP WITH A DIE MANUFACTURING PROJECT? THE DIAN STAMPING HAS YOU COVERED!

The DIAN STAMPING has actually dealt with tool stores, production centers, and product manufacturers worldwide. Leveraging this experience, we can assist producers style and construct robust tooling to equal production requirements and part quality. The Phoenix Group can discover lasting services to numerous making difficulties from tooling buy-offs, formability analysis, analytical, and pass away abilities training.

Contact us today at +86(576) 84288255 or [email protected] demand an assessment online.